The Pz.Kpfw. Maus is one of the most famous German tanks. It was the heaviest tank ever built in history. Opinions about the Maus tend to be extreme opposites, some believe that the Maus was the Wehrmacht's last hope, others say that it was the proverbial straw that broke the back of German industry.

As usual, the truth is somewhere in the middle. The Maus was unlikely to save Germany, but it would have been a nasty thorn in the side of the Allies if it ever reached the battlefield. German industry didn't need to apply any kind of heroic effort to produce it. However, the damage dealt to German industry was so severe that the Maus was impossible to produce by the fall of 1943.

The last metamorphosis

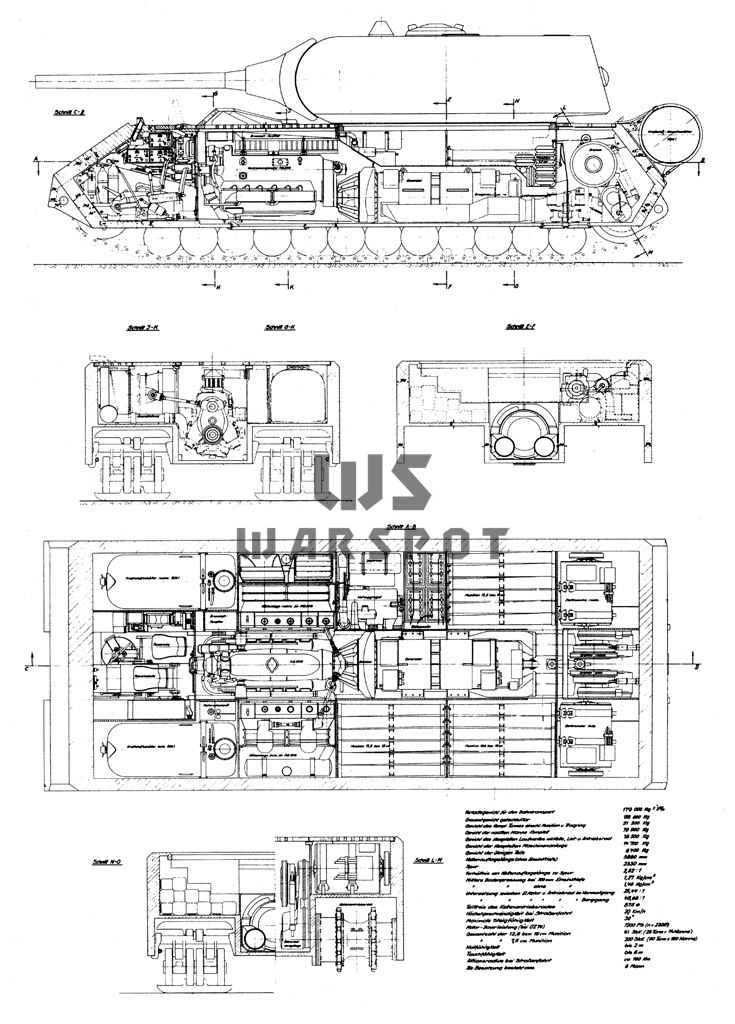

The general layout of the Pz.Kpfw. Maus superheavy tank was finalized by early 1943. The turret was in the rear, the major components settled in place. However, changes to the design continued. The hull changed, for instance the model presented on January 21st, 1943, had additional armoured plates added to the front to cover the tracks and idlers from enemy shells. At the same meeting it was decided to enlarge the diameter of the driver and radio operator hatches to 500 mm and a hull machine gun was discussed.

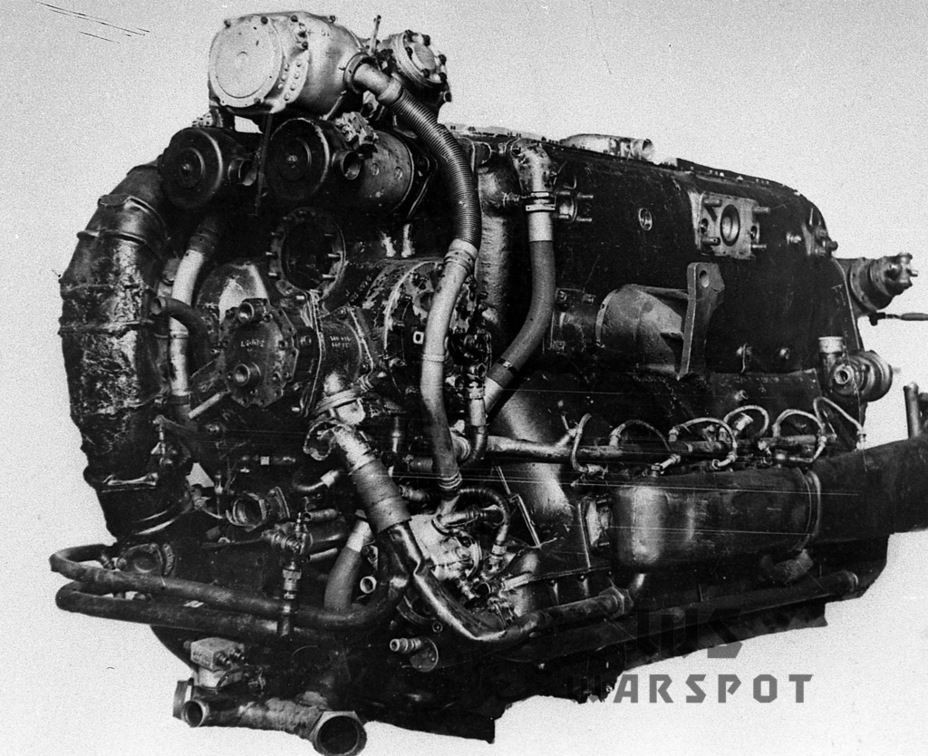

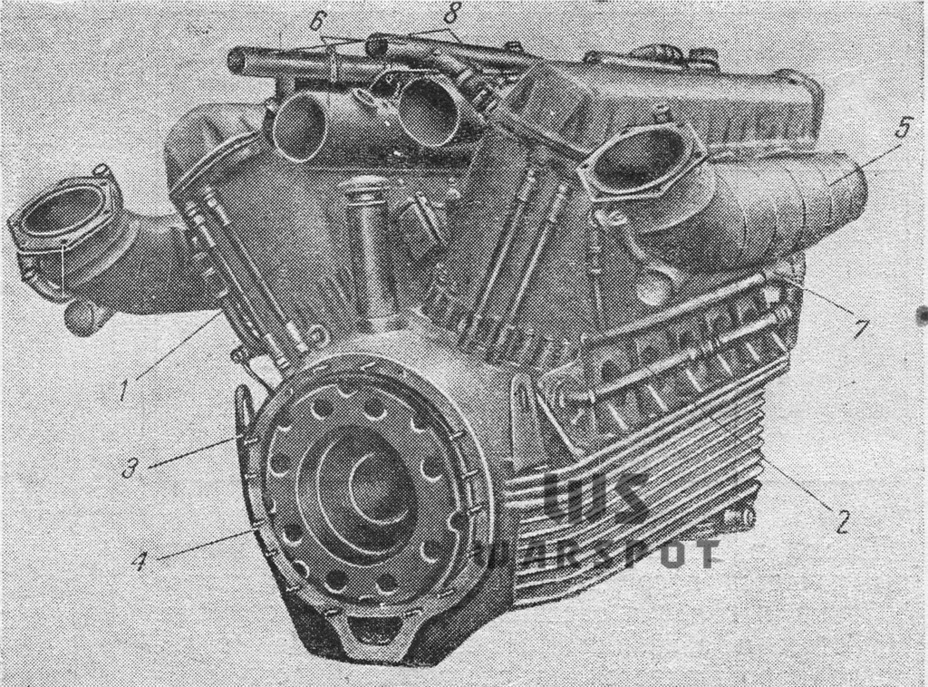

The engine and transmission saw even more changes. It was clear by February of 1943 that the diesel engines described by the Typ 205A and Typ 205B projects would not be ready in time. An alternative was urgently needed, and it was found fairly quickly. This was the V-shaped Daimler-Benz DB.603 engine.

The 44.5 L engine was put into production in May of 1942 for use in bombers. The DB.603 put out 1750 hp, which was excessive for a tank. Porsche made a request to the Reich Ministry of Armament on February 17th, 1943, for a reduced power variant of the motor. The engine, named MB.509 at the factory, was reduced in power to 1200 hp. The 6th Department of the Armament Directorate ordered 8 engines in total with production expected to start in August and last until the end of 1943. The order was later expanded to 180 engines due by November of 1944. That many MB.509 engines were not produced.

A decision was made to replace the individual driver and radio operator hatches with one large one. Deflectors were added on the engine deck to protect against gases from the 7.5 cm KwK L/36. A 1000 removable fuel tank was added to the two main fuel tanks. This tank could be quickly dropped if necessary. The running gear also transformed. Heinrich Kniepkamp, the head of the 6th Department of the Armament Directorate, proposed a new track link that was 30% lighter at a meeting on January 21st, 1943.

Porsche K.G. received a report by early April warning that the mass of the tank reached 179.3 tons and the growth tendency had not decreased. The weight gain of over 30 tons did not pass without a trace. This mostly affected the suspension. An alternative to a bogey suspension with parallel torsion bars had to be found.

Škoda developed a new suspension in March-April of 1943. Four interleaved road wheels were grouped together on a single beam. Each pair had its own volute spring. Two support rollers were added to the top of the beam. The tank was supposed to have six bogeys per side. This gave the Maus a total of 48 road wheels, which spread out its weight better.

A number of changes, some unexpected, were made to the armament. On January 23rd, 1943, Hermann Köbe Feuerwehrgerätefabrik received an order from Krupp to develop a flamethrower with a range of 150-200 meters. Wooden models of the flamethrowers were ready by March 1st. The developers estimated that the actual range was about 100 meters if 33 L of fuel per second were expended. Two flamethrowers would be installed in the left and the right sides of the rear plate. The flamethrowers, which were operated by the radio operator, added another 5 tons to the weight of the tank. The aforementioned drop tank was initially designed for flamethrower fuel. The flamethrowers were approved for production but only models were ever built.

Another exotic weapon was discussed as of February of 1943. A 20 mm Mauser MG-151/20 autocannon was planned for installation in the turret, to the left of the gun mantlet. It was supposed to be aimed from a special cupola with a maximum elevation of 30 degrees. 250 rounds of ammunition would be carried for the AA gun. This was later reduced to just 80. One MG-151/20 was sent to Krupp and the idea of an AA gun mount died at the blueprints stage. Considering that it would have to be aimed horizontally by turning the whole turret, the effectiveness of this gun would be close to zero.

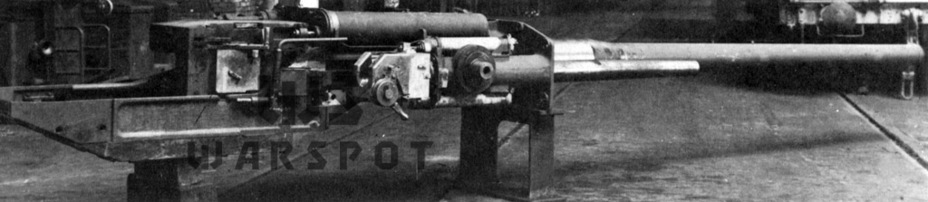

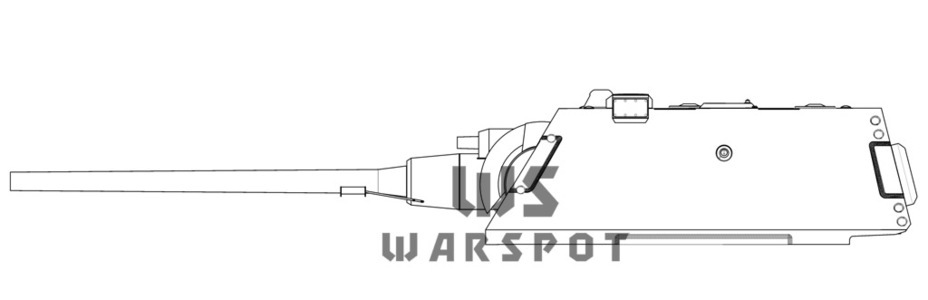

Although the 15 cm KwK L/38 was mentioned as the main weapon of the Maus until at least March 12th, 1943, an alternative appeared by February. This was a 128 mm L/55 gun without a muzzle brake. Designers rejected any gun that was longer since the turret would have to be changed to accommodate it. A special periscopic sight was chosen instead of any assortment of proposed telescopic and panoramic sights.

The 128 mm gun was indexed 12.8 cm KwK (Maus) L/55, later 12.8 cm KwK 44 L/55. A slightly modified version was late built as the 12.8 cm Pak 44 L/55. It was used on both towed mounts and the Jagdtiger tank destroyer.

Judging by blueprints and requirements, the flamethrowers in the rear section of the tank were deleted by the spring of 1943. However, they were still present on models. The AA mount was missing from both the blueprints and requirements.

51.5 tons of the overall mass included the turret and ammunition. 25 single piece 128 mm and 50 75 mm rounds were located in the turret. The rest of the ammunition (36 128 mm and 150 75 mm rounds) was stored in the hull. A decision was made on April 16th to add submachine gun ports to the sides of the turret. The ports were equipped with ball mounts developed by Daimler-Benz.

The AA mount was still not done for. Another MG-151/20 was sent to Krupp for experimental work on April 16th. The next change to the turret followed on April 29th. The commander lost his cupola and instead gained a rotating periscope in front of the right turret hatch.

The model presented to Hitler on May 14th, 1943, was not entirely the same as the most up to date blueprints. It still had a commander's cupola and flamethrowers. Nevertheless, the model did its job. Hitler approved mass production of the superheavy tank.

However, the model raised a lot of questions of Guderian's part. The Chief Inspector of the Armoured Forces met the superheavy tank idea coldly and showered it in justified criticism. The 6th Department also got an earful. The «genius» idea of arming the tank with a 20 mm gun instead of a coaxial machine gun came from them. They also insisted that the tank's bow machine gun be removed.

Guderian's criticism was taken to heart. The front hull and rear received ball mounts for the MG-34. A 37 mm AA autocannon was proposed instead of the MG-151/20. The AA gun mount returned to the turret of the Maus, but not for long. It was cancelled again on May 21st, since it took up too much space.

The blueprints showed the Maus' width as 3700 mm, but various improvements would only lead to its increase. This was unacceptable. This width was the maximum possible if the tank would be transferred by railroad. For the same reason the decision to produce the tank with 170 mm of side armour starting with the third vehicle was made on June 26th, 1943.

Various changes would be introduced later, and the look of the Maus would only be finalized in November of 1943.

Greetings from Bomber Command

Preparations for Maus production began in early 1943. Krupp was chosen as the supplier of hulls and turrets, assembly would be performed by Alkett (Altmärkische Kettenfabrik GmbH) in Spandau. The first Pz.Kpfw. Maus was due by the end of 1943, and mass production would begin in 1944 at 10 tanks per month. Contract SS4911-0210-9801/43 was signed with Krupp for 120 hulls and turrets on February 22nd. The contract required the first two hulls to be shipped to Alkett in November, 4 in December, 6 in January, 8 in February, and 10 per month starting in March. The first turret was due on October 15th, with further deliveries lagging the hulls by a month. On February 23rd Krupp signed contract SS4911-0006-6387/42 with the 6th Department for the first 6 hulls. Krupp also received the contract for guns for the Maus.

Work on creating means to transport the Maus on rail carried on in parallel. Work to create a rail car was assigned to the Austrian Simmering-Graz-Pauker company (Simmering Werk, Vienna) that already worked with Porsche K.G. during the building of Typ 100 and Typ 101 tanks.

The task given to Austrian wagon builders was non-trivial. A railcar that supported 180 tons and could fit the tank very precisely (due to its excessive width) was needed. Simmering-Graz-Pauker developed a 14-axle railcar called Schwertransportwagen für Gerät 205 (heavy transport platform for device 205). The 72.5 ton railcar consisted of three sections. The main one was a 6-axle platform which had 4-axle railcars attached to the front and rear to make maneuvering easier. The total length of the railcar was 27 meters. The mass of the railcar and the tank reached a truly monstrous 250 tons. A separate production line was allocated for the Schwertransportwagen für Gerät 205.

A decision was made in June to increase production from 120 to 141 tanks, but Guderian entered in an open conflict with the Tank Commission. He rationally maintained that it was more reasonable at first to develop a 5 tank pilot batch, test it at the front, and only then think about mass production. Monthly production was capped at 5 vehicles on July 1st, but the plans for a pilot batch remained in effect.

The hull of the first Maus tank was built by Krupp on July 7th. The fear of surpassing the maximum dimensions was justified. The 3700 mm wide tank was actually 3717 mm wide. The hull still had cutouts for flamethrowers which were welded over before assembly. Work began on six more hulls (plates were cut and preparations for assembly were underway) in the middle of July. On July 17th the Pz.Kpfw. Maus V1 received serial number 351451. The rest of the pilot batch tanks had serial numbers up to 351455. Turrets received analogous serial numbers.

Krupp prepared plates for 30 hulls by the end of July 1943. Two hulls were nearly finished, five more were in various stages of assembly, and two more were fully cut and delivered to the assembly workshop. Krupp was capable of producing 120 hulls on its own. Alkett also didn't seem to be having any trouble. The production plans of 10 Maus tanks per month seemed realistic without any kind of overloading of German factories.

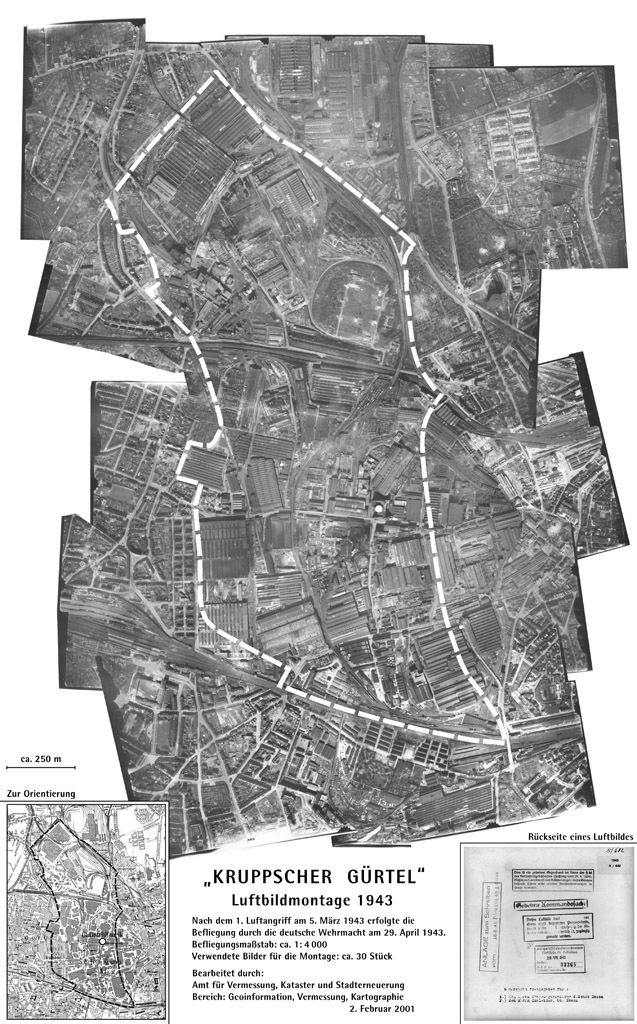

The superheavy tank had a more serious opponent than Guderian: British Bomber Command. The Royal Air Force had no idea about the Maus, but British bombers played a key role in the fate of the tank.

The first strike against the superheavy tank program was delivered on the night of March 5-6th, 1943. 362 bombers bombed Essen over the course of 40 minutes with HE and incendiary bombs. The city, its factories, and Krupp. Documentation on the Maus turret and armament was destroyed in the raid as well as the full sized model. The production of the first turret was delayed by two months.

The Germans rapidly restored the documentation and built a new model turret, just in time for it to be destroyed by a new wave of bombs a month later. The next major strike came on April 3rd-4th. 348 bombers took to the skies over Essen. This delayed the production of the turret by another two months.

The third and decisive strike against the Pz.Kpfw. Maus was delivered on the night of June 25-26th, 1943. Bomber Command wanted to put an end to the Battle for the Ruhr. 705 aircraft dumped their deadly cargo over Krupp's factories and Essen over the course of 50 minutes. 500 people died, 12 went missing, 1208 were wounded. 2852 houses were destroyed. Krupp's factories also took a heavy blow: 51 factory buildings were destroyed and 83 were seriously damaged.

Gustav Krupp, the director of the Krupp group, had a stroke on the very next day that he never fully recovered from. Neither could the superheavy tank's hull production. On August 18th Krupp informed the Armament Directorate that hull production could resume after 7 months, turret production needed even longer: 8 months.

An even more discouraging report was submitted on August 25th. Krupp could only deliver 30 sets of hulls and turrets. The first hull was planned for delivery to Alkett in September, two in October, one in November, one in December, two each in January and February, three in March, four per month from April to June, and two in August. The shipment of the first turret was scheduled for November, two in December, one each in January and February of 1944, two in March, three in April, and four from May to September.

This was just the tank's death throes. The damage to Essen was so heavy that the Maus was holding it back. Instructions from the Armament Directorate to redirect all resources to producing StuG 40 armour came on October 27th. The order for six Maus tanks was reduced to two hulls and one turret on November 5th. The superheavy tank died before truly being born.

Monster from Böblingen

Assembly of the first production Maus dragged on. The Typ 205/I hull (as the first prototype was sometimes called) arrived in Spandau on September 26th, 1943. Work on it was not a priority. In addition to the StuG 40, Spandau was responsible for Nashorn production. Berlin came under attack from 764 British bombers on the night of November 22nd-23rd. Alkett and Siemens were hit hard, and the official cancellation of the Maus turned into a mere formality. There was no factory left to mass produce these tanks.

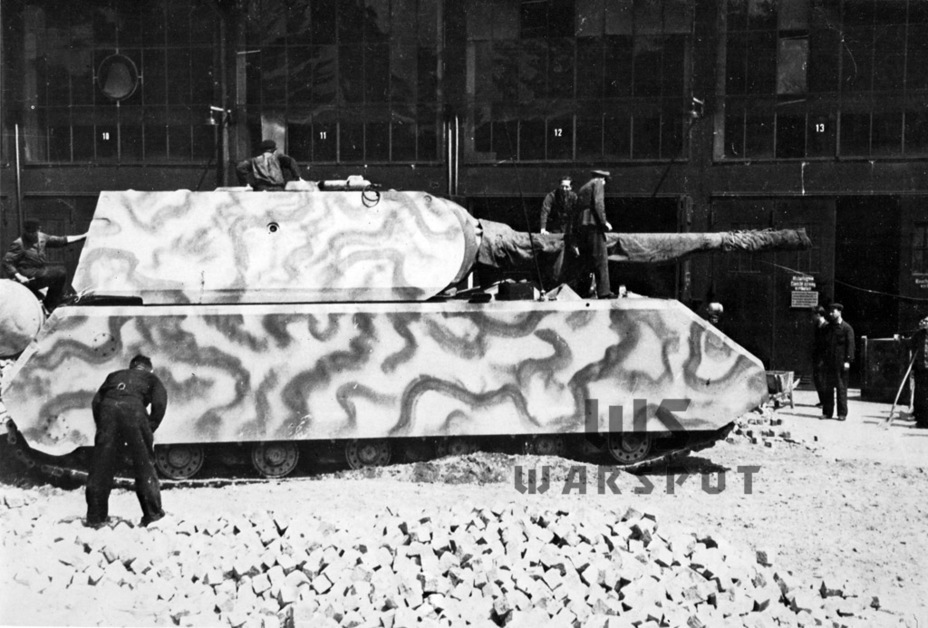

The main goal now was to assemble the prototype so it could at least move on its own. Since the number of turrets ordered was reduced to one on November 5th, a welded dummy with massive lifting eyes was installed instead. The Maus V1 set out on its first test drive through the territory of the Alkett factory on December 23rd, 1943. The test drive was illegal, since Speer did not give permission to carry it out. Even though photographing this tank was forbidden, photos of this test drive were made.

The Typ 205/I was not even painted for its first run. It was only primed, hence the mistaken opinion that the tank was painted dark gray. The Maus received its first markings: one of the factory's workers wrote the word Mäuschen on the sides and rear and drew a small mouse underneath. The first test drive was also a mobility trial. Alkett's grounds were covered in debris due to being subjected to bombing just a month prior. Karl Gensberger, a test driver from Porsche K.G. drove the tank. Porsche himself monitored the trial from Stuttgart by telephone.

The trials were a success. Gensberger easily maneuvered through a narrow passageway between a building and a fence and crossed piles of debris. The only issue was that the tank could only turn in place. The developer of the transmission, Zadnik, had to be retrieved from sick leave for him to explain over the telephone the nature of the issue. The tank could turn in all modes of operation after the issue was corrected. The trials were a success. Gensberger noted that it was easy to drive the tank, a feature of all Porsche creations with an electric transmission.

Since Alkett could not perform assembly, another location was found. The Maus V1 was loaded on a train on January 10th, 1944, and sent to Böblingen, a suburb of Stuttgart that was home to an airbase, a Klemm aircraft factory, and a military base. Stuttgart proper housed Porsche K.G. and Daimler-Benz A.G. Alkett began work on the Typ 205/II on the very day that the first prototype arrived at its destination.

Since the issue with dimensions didn't go anywhere the train carrying the Maus V1 had to avoid tunnels and going under bridges with narrow spans. When going over bridges, the impressive weight of the tank and its platform had to be accounted for. The tank could climb on the platform and leave it on its own.

The Maus V1 was sent to the workshops of the 7th Reserve Tank Battalion upon its arrival on January 14th for final assembly. The tank travelled for 5 km from the train station to the workshops without incident. On the next day the tank travelled for 2 km off-road. Alkett tracks worked well, the Maus could keep moving even when submerged up to half a meter in mud.

The next two weeks were taken up by final assembly. Trials continued on January 31st. The tank travelled for a total of 14 km, 4.6 of which were off-road. The road wheel tires on the inner row wore off during the first stage of trials. This was expected and new wheels were ordered. It was permitted to continue testing with the old wheels in the meantime. The Maus V1 received a camouflage paint job: red-brown lines on top of the yellow base coat. An inverted hammer and sickle with crooked letters ГЯП underneath were drawn on the sides of the hull, and upside down red stars were drawn on the turret. The aim was to confuse unauthorized observers. Captured Soviet tanks were being tested at the same proving grounds and the Maus V1 with stars and sickles was supposed to look like a trophy from the Eastern Front. The tank was constantly improved during trials.

It turned out that the MB.509 engine requires high octane gasoline. This problem was solved with aircraft additives.

Alkett assembled the Typ 205/II while the first prototype was being tested. This was the first true Maus with a turret and armament. A number of issues with the assembly delayed its debut. A decision was made to complete assembly in Böblingen in February of 1944. The train with the tank arrived on March 10th. The Maus V1 was used as a tractor. The Typ 205/II was first pulled off the platform with a cable then linked to the Typ 205/I and towed to the workshops of the 7th Reserve Tank Battalion. The road was partially iced over, but no issues were observed. This trial showed that the Maus can move not only itself, but a weight of comparable mass.

While assembly of the second prototype was being completed the first tank continued to rack up mileage. The tank crossed a 1 meter deep stream on March 15th, climbing over one of its banks. The slope at that point was 45 degrees steep. The rear trials awaited it on the next day. The tank set out for its usual drive along the proving grounds of the 7th Reserve Tank Battalion to test its off-road mobility. The driver did not know all the nuances of the proving grounds and drove into a bog. The battalion's lighter tanks navigated it without issue, but it was a trap for the 180 ton Typ 205/I. It sank into the ground more than 1.5 m deep.

Ferdinand Porsche and employees of his design bureau arrived on the scene. They could do nothing but examine the bogged down vehicle. 20 soldiers with shovels were sent to the tank. They spent a whole day digging it up and making a ramp behind it so it could climb out of the trap. The tank was started up once more when the work ended. Logs were placed under the tracks to increase traction. The tank finally managed to escape. Modernized suspension bogeys finally arrived and were replaced there and then. The Maus wnt through field repairs for the first time.

The turret for the second prototype was sent from Essen to Böblingen on May 3rd, 1944. It looked slightly different by then. The designers rejected single piece ammunition back in 1943, opting for separate propellant loading. The ammunition racks had to change as a result.

The tank received a rotating periscope based in the Gundlach principle instead of a commander's cupola. The rotation was not ideal, since at certain angles it was impossible to look into. The dead zone also increased compared to the commander's cupola, and the periscope also needed a cut in the side armour which didn't help with its toughness. An analogous periscope was supposed to be installed in front of the loader's hatch. This periscope can be seen on the diagram of the tank's internals and blueprints dated late 1943. An opening was cut in the roof in the necessary place.

The turret also received a deep wading kit. Special equipment was designed in 1943 to seal the gun mantlet and install a large air intake pipe. The second prototype could move underwater, although this was never tested. Both Maus tanks had ports in the rear that allowed them to drive under external power.

The assembly was suddenly expedited in early June. Guderian was supposed to visit Böblingen and the turret had to be installed urgently. Assembly was rushed on the night of June 7th-8th. The turret ring was a little crooked. The gaps were filled and the turret was installed anyway. Guderian suspected nothing. The tank could still drive on its own.

The first test drives were performed before the tank was painted. Trials of the turret had to be delayed several times since there were issues with the traverse and elevation mechanisms. The first trials had to be performed using the unpowered traverse only.

The submachinegun ball mounts were also an issue. They only arrived on July 12th. They broke down turing testing after installation. The tank remained in use for some time with just holes in the sides, in late 1944 they were welded over.

The turret was fully equipped with sights and optics only in July. The tank only received a radio then.

Mobility trials were successful, but not problem-free. The Daimler-Benz M.509 gasoline engine installed on the second prototype had issues with its valves which led to a breakdown at least once. The trials showed that the tank consumes 305 L for 10 km of travel off-road. Like the first prototype, the tank could drive off-road without too many issues, but the ground pressure made itself known once in a while. Asymmetric grousers were tested in July, although to little effect. Several track links broke during trials. It took a team of six men 8 hours to replace them at the workshops. The perforated road wheels showed no advantages over the old ones and they were replaced.

Death of a mouse

Porsche K.G. and Krupp continued work on the tank even though its end came in November of 1943. Hitler raised the issue of using Maus turrets on fortifications on September 30th, 1944. The proposal was not senseless, as there was already a backlog of turrets and only few changes were needed to convert it into use in a bunker. Krupp prepared documentation for such an installation by early November, but the project did not proceed past blueprints. Work on installing a rangefinder also ended here. This was first proposed in March of 1943 and the first draft appeared in the fall.

The story with a rangefinder continued in 1944. Krupp began to design a new turret in March taking into account all of the wishes and requests that accumulated. The turret had the same armour but was shorter, most importantly it was easier to produce. The front of the turret was flat instead of a complicated curved piece that permitted ricochet downwards. A gun maintenance hatch was added to the back of the turret. The armament was also changed. The 7.5 cm Pak was placed above the 12.8 cm KwK 44 L/55. This layout made the loader's work harder but also protected the engine deck from the blast of the gun. The design also lacked a front machine gun or a bomb thrower, but those were unlikely to be left out.

Almost no documentation about the new turren known as the Maus II Turm survived. The only known drawing, Bz 3276 dated March 23rd, 1944, compares the turret to the Heuschrecke 15 SPG which was armed with the same gun. The drawing indicated that the weight of the turret was 50 tons.

Work on the Maus II Turm did not begin accidentally. Even though mass production was cancelled the project was not yet dead and buried. Successful trials of the Typ 205/I showed that the design had potential to live. Guderian remarks in his monthly report for February of 1944 that he questioned the sense in Maus production at a meeting with Hitler. Therefore, Hitler still had hopes to see the armoured giant in production.

Porsche proposed that the Maus program should be reanimated in March. He received permission to continue his work. Changes to the hull had to be made since the turret ring diameter was a bit larger. The first blueprint of the Maus II was prepared by March 15th, 1944, and on April 8th the 6th Department signed contract SS 4911/0006/3040/43 for a 1:5 scale wooden model.

The question of hull production at Krupp was explored in parallel. As of March 18th, 1944, there were 7 hulls in various stages of completion and 8 sets of plates prepared. There was also enough armour for production of 15 more hulls and 9 turrets. This was enough to begin mass production, but Krupp was overloaded with other work. There was also the issue of assembly, as Alkett was also busy.

Nevertheless, Krupp continued some work. Six hull and seven turrets (not counting the ones used in the prototypes) were in various stages of completion at the end of the war. However, by mid-July of 1944 it was clear that there was no point in working on either the Maus or its competitor, the E-100. Hitler ordered that the design and production of superheavy tanks should cease. Nevertheless, various work on modernizing the Maus continued until early 1945. Around this time the second prototype received the MB.517 diesel engine. It is not known when this happened, but a letter dated December 1st, 1944, says that the engine was already installed but not yet tested. In any case, these trials would have already been pointless.

Translated by Peter Samsonov. Read more interesting tank articles on his blog Tank Archives.

Sources:

- BAMA (Bundesarchiv);

- US National Archives and Records Administration;

- Central Archives of the Russian Ministry of Defence;

- Igor Zheltov's archive;

- Panzer Tracts No. 6-3 — Schwere-Panzerkampfwagen Maus and E 100 development and production from 1942 to 1945, Thomas L. Jentz, Hilary L. Doyle, Panzer Tracts, 2008, ISBN 0-9815382-3-1;

- Special Panzer Variants: Development — Production – Operations, Walter J. Spielberger, Hilary L. Doyle, Schiffer Publishing, 2007;

- Kampfpanzer Maus: Der überschwere Panzer Porsche Typ 205, Michael Fröhlich, Motorbuch verlag, 2013, ISBN 978-3613035485.